The Girl Who Made the Cherry Pie, Posted on Monday, January 5, 2026

- January 5, 2026

- |

- Posted By: Scott Family Collection

In June of 1936, Elizabeth Scott Carrington was working in Philadelphia as a nursing instructor. The Democratic National Convention was taking place nearby and she walked over to see if she could find someone her father knew, Josephus Daniels. Among other things, Mr. Daniels was the editor-in-chief of the News and Observer (Raleigh). She had met Mr. Daniels many years before when he came to her parents’ home for lunch one day.

She spotted Mr. Daniels right away and walked up to him. She introduced herself but before she could get more than a few words out, he interrupted her, saying, “You’re the girl who made the cherry pie!”

That must have been quite a pie. The cherries came from a Morello cherry tree on her parents’ property. Elizabeth said that she had never seen one anywhere else. The family also had a greenhouse where they grew their own lemons, but that is another story.

Elizabeth probably used the kitchen tool pictured here to remove the pits when she made the pie. Morello cherries are a medium sized cherry with a tart flavor and are excellent for baking and canning. I wonder if she made a lattice top for her pie. Elizabeth was known for her cooking and baking, and although she majored in Home Economics in college at Flora MacDonald, went off to nursing school in Philadelphia after graduation. And the rest, of course, is history.

Crazy Quilt, Posted on Monday, December 15, 2025

- December 15, 2025

- |

- Posted By: Scott Family Collection

When I hear the word, “quilt,” I think of the one my mother left me. It has a pattern of blue baskets on a white background.

Quilting has been around for thousands of years, but the idea is always the same. A quilt has three layers, a decorative top layer, some padding, and a plain backing. The three layers are held together by rows and rows of tiny stitches.

The end product is not only practical, it provides the creator or creators with an opportunity to show off their ingenuity and skill.

A lot of quilts are unsigned, and we know nothing about who made them or why. Others are handed down from generation to generation along with the story of their origin and maker(s).

I do know who made my quilt because her name is printed on a small tag attached to the backing. Her name was Betty and she lived in Arkansas.

I have often thought about Betty. How did she decide to make this particular quilt? Was blue her favorite color? It was my mother’s.

Betty made her quilt by cutting what we call whole cloth into shapes and then stitching the shapes back together into a repetitive and decorative pattern.

But how do you make a quilt if all you have is a bag of scraps left over from other projects such as clothing or draperies?

Behold, the crazy quilt.

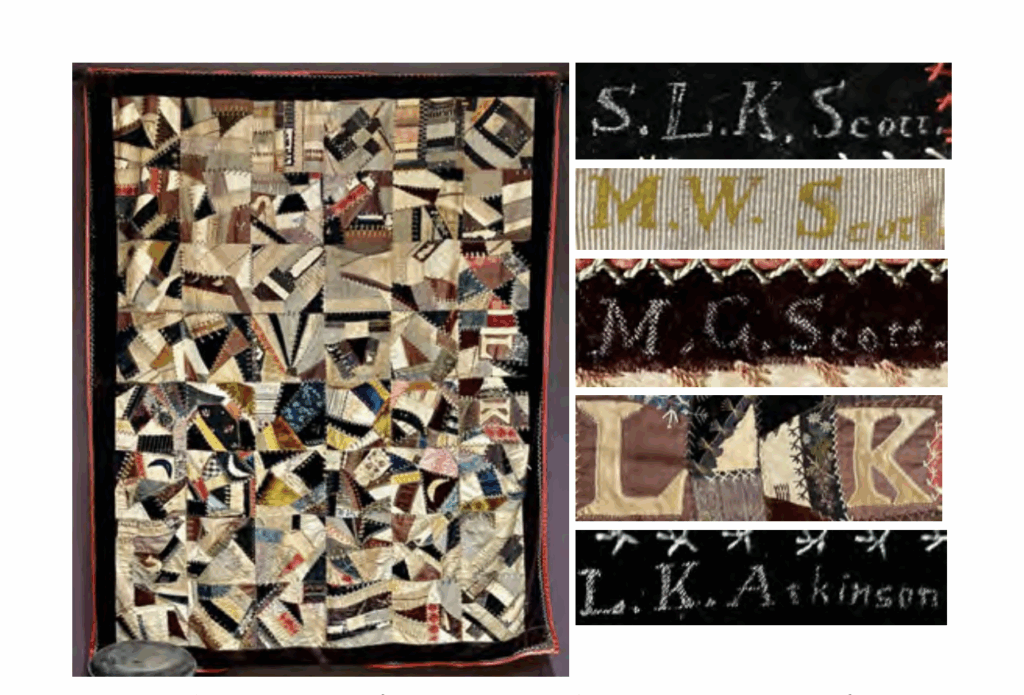

Back in the late 1800s, five women got together and created the quilt you see here. It was too small and too fancy to be used as bedding. Most likely it would sit in the parlor and be used as a lap robe on chilly days. Now it hangs on one wall in the Scott Family Collection.

Unlike my mother’s quilt, this quilt has the names of the makers worked into the pattern. See if you can find them. If not, I have provided their signatures to the right of the quilt.

They are Sue Lizzie Kerr Scott, Mamie White Scott, Margaret Graham Scott, Lizzie Kerr, and Lizzie Kerr Atkinson.

The Bull Moose Comes to Town, Posted on Monday, December 8, 2025

- December 8, 2025

- |

- Posted By: Scott Family Collection

In the spring of 1912, Lizzie Scott, then age 47, took a train from Mebane, North Carolina, to Raleigh, the state capitol, to visit her daughter Josephine Scott Hudson. Josephine was a new mother, and as such, was grateful to get some help from her own mother, who was very experienced in things “baby.”

Lizzie’s husband, Robert, wrote her frequently to update her on events at home. He mentioned that her asparagus was doing so well, he planned to have some for dinner. The potatoes, however, produced only disappointment. Equally disappointing were the geese. Despite the use of an incubator to keep the eggs warm, no goose eggs had yet hatched.

In better news, Robert informed Lizzie that he had just sold a horse to Mr. and Mrs. Maltbie for 137 dollars.

And there, among the news and updates, is a little gem.

Robert suggests, “I don’t see why you should not stay to hear Roosevelt. It will be your best opportunity to see & hear him. We can get on alright.” Robert goes on to ask about Josephine and the baby and chides Lizzie gently for not writing more, explaining that their daughter Margaret was impatiently waiting to hear about her new nephew.

Theodore Roosevelt, who was President from 1901 to 1909, did not like how things in the U.S. were going. In 1912 he decided to run for President again, this time as a third-party candidate. The new party, the Progressive or “Bull Moose” party, came from a comment Roosevelt had said about himself; he was as strong as a bull moose.

To promote his campaign, Roosevelt went on a whistle-stop tour, visiting 22 different cities in North Carolina including Greensboro and Raleigh. It is ironic that when he spoke at what is now The University of North Carolina at Greensboro, he addressed a room full of people who were unable to vote for him. Those people were female students! The right to vote would not be granted until 1919, so the next presidential election they could vote in would take place in 1920.

We don’t know today if Lizzie did attend the rally for then candidate Roosevelt. I hope so. It’s not every day you get to watch history being made.

My Life in Cotton, Or, How I learned to Predict the Future, Guest blog post from Chris Ackiss, Posted on Monday, December 1, 2025

- December 1, 2025

- |

- Posted By: Scott Family Collection

Back in the 1990’s my plan was to work in the tobacco business after I graduated from college. And I did find a job with a tobacco warehouse, but this work is seasonal, so when the market ended, so did my job.

My next job was in the cotton business, which as it turned out, was seasonal also.

From about September until a little after February I had a job in Wilson, North Carolina. I stood in a chilly warehouse all day, checking in truckloads of cotton.

I learned a great deal about cotton from that job.

After the farmer harvests the cotton, it is packed into modules which typically weigh several tons. The modules are loaded onto a special truck and shipped to the gin to be cleaned.

Modern day cotton gins are similar to the one originally designed by Eli Whitney. They are just faster and more automated. The ginning process removes most of the trash and seeds from the raw cotton. The seeds can be fed to cattle or processed into cotton seed oil.

The cleaned cotton is packed into 500-pound bales, ready to be shipped to a warehouse. Before being loaded onto a truck, the cotton is sampled for grading.

One half of the sample goes to the government grading office; the other goes to the warehouse where the cotton will be stored. The warehouse stores the cotton until it is time to go to the mill. Running a warehouse is a competitive business. The farmers have a choice of where to take their cotton; the warehouses rely on the revenue they get for storing the cotton until it is sold to the mills. When the cotton is sold, it gets sent to the mill to be made into cloth and then clothing.

I learned a lot about cotton from that job in the warehouse. How it is grown, harvested, ginned (cleaned) and sold. But by the end of February, I was looking for a job again. I liked working in cotton and was pleased to find another job in the cotton industry, this time at a mill.

Did you know that cotton comes in different colors? Well, I do now.

As I said, my next job was at a cotton mill. In order to be good at my new job, I needed to learn a great deal more about cotton.

To prepare me for my job, my new bosses sent me off to school for ten weeks.

The first class was held at Texas Tech. There I was trained on grading cotton. The training class lasted for two weeks and then I went to Rhodes College in Memphis, TN for eight weeks to learn everything I could about the entire process from planting to consumption. This was a wonderful experience. The students were from all over the world. Cotton is big business, after all! While at HVI school at Texas Tech I was in the panhandle of Texas. Lubbock to be exact and it is a cattle town for sure with a stock yard. When the wind blows you can smell the stockyards all over town. While the food was good, I prefer eastern NC BBQ. However, if you are ever in Memphis there is a place for ribs called the Rendevous. It is a must.

After my training, I was able to help the mill a lot and became a quality auditor for a short period. I would go out to the mills that we owned, I think it was like 5, and do audits on the laydowns that we shipped from the cotton warehouse to the mill to make sure they were using the cotton as planned.

I did not stay in the cotton business, but the entire experience prepared me for other jobs that required great attention to detail, quality control, and the ability to anticipate the future (not predict, just anticipate). But more about that later.